The latest Pitti Immagine Filati event took place in January from 25th to 27th. It involved the presentation of the knitwear yarns collections created for the season Spring-Summer 2024.

Our visitors to the fair are Laura and Daniele, knitwear designers who operate in our Research and Development department here at Maglificio FMF. Since they are the ones taking care of all the new knitwear samples that are showcased all year round in our showroom, they are responsible of all the developments and constant creation of new men’s and women’s knit pieces and swatches to be displayed to brands that are already our customers or to potential new ones. Therefore, they are always looking for new sources of inspiration. From the trends researched online on specialist sites and the photographic material relating to the fashion shows, to the use of fashion and knitwear magazines, up to market surveys, in local physical stores or online, they analyze the market and then develop their ideas.

Obviously, the two of them are therefore always looking for new and fascinating yarns, as well as particular knit stitches and structures that have not yet been tested in our company, to use themselves or to know in detail in order to be able to offer that knowledge to our customers. In fact, it often happens that when a brand client is looking for something specific or asks us to suggest yarns, send photos from our archive of garments and knit stitches, to be used as a starting point for their collections, Laura and Daniele are consulted to find the most aesthetically pleasing solutions. And of course, the solutions needed to reach an effect closer enough to what is required. Every phase of this process always takes place keeping in mind the yarn cost, research level and the processing costs ratio, considering the price budget and the development required starting from the simple creation of a knit swatches to a customer’s first sample of a new garment.

Being at Pitti Filati, our designers visited just a few stands of the spinning mills with which they have an active collaboration during the year, having little time at their disposal. The first of their visits is at the stand of one of the historical Prato based company Cofil to see the collection of yarns that they are proposing.

The latter always offers very interesting yarns in the summer collections, many are those with particular compositions, often also accompanied by certifications relating to the traceability and sustainability of the raw materials and the manufacturing processes necessary for their production.

In recent years, clients have in fact become increasingly demanding regarding the choice of yarns to be used in their collections. They make more and more specific requests, in terms of appearance and count of the yarns, and obviously the compositions and certifications relating to their sustainability. In the latest years we started using exponentially more yarns that are accompanied by these kinds of certifications.

Among these many certifications, it is important to mention the Oekotex Standard 100, now indispensable for using any type of yarn in our company. This certification certifies that the yarn has been tested by the Oekotex body and does not contain heavy metals, aldehyde form or other harmful substances, once unfortunately widely used in the fashion industry. Or at least it certifies that these substances are not present beyond the limits permitted by the global laws to be respected for the current production of knitting and weaving yarns.

In addition to this certification there are a lot more, including all those related to vegetable fibers typical of the summer yarn collections, such as for example the GOTS and OCS certifications for cotton and linen, and FSC and ECOVERO for sustainable viscose because they are made from cellulose pulp coming from trees grown in certified forests. This means that they use a type of cultivation that is respectful of the environment and attentive to non-deforestation of natural areas at risk or protected.

We then visit the stand of the Pinori Filati spinning mill from Prato for a brief greeting, up to the Olcese Ferrari cotton mill, whose stand displays some garments made by us for the promotion of their yarns at the fair.

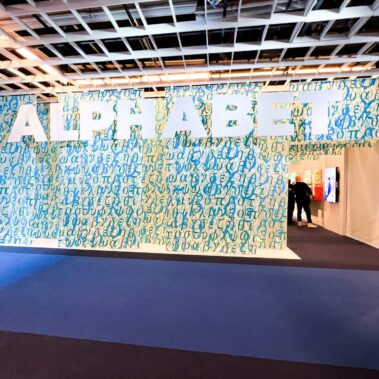

We arrive at the trends area of Pitti Filati, whose theme for this edition is called Alphabet.

Alphabet is the title because the theme develops all around the letters of the Alphabet. Inside we find the usual panels with knitted swatches with multiple processes that depict letters of various different alphabets. There is also no shortage of knitwear displayed on mannequins, with beautiful knitting processes and techniques that challenge imagination and pure technique. Some processes really capture the attention of visitors, often intent on wondering what is the technique used to create a certain knit stitch or particular design.

Ultimately, a certainly new and interesting trend area, which, as usual, has not disappointed expectations.

After a tour of the Knit Club where we appreciate the garments exhibited by some Italian knitwear factories guests at the fair, we stopped at the stand of the German manufacturer of knitting machines: Stoll.

It is the manufacturer of the knitting machines that we mainly use in our company, so we are very intrigued by this stand, in terms of new techniques and processes they have experimented with, as well as the new machines they displayed. The machines made by this company are infact many and various, not only for the thickness of the yarns they can knit, but also for the different characteristics and functionalities.

Outside the stand, a panel showing 6 black knitted swatches catch our attention. These swatches all reproduce the same knit stitch but in different “sizes”, despite being visibly made by the same machine, because they are still linked by the separating thread that connects them. In fact, they are swatches created with the intention of showing all the potential of the multi-gauge machine that created them. It is a very particular model of electronic knitting machine. The model is called CMS 830 2.5-5 and is in fact both a 5 and a 3 gauge, with a potential that nearly matches a 1.5 gauge machine. Allows the use of yarns suitable for 5-gauge machines and those for 3, 2.5 or 1.5 gauge on its needle beds, therefore almost up to the enormous ones usually only suitable for hand-knitting or crochet-kind knitwear. These features make of it a real multi-gauge machine, a machine that truly challenges the limits of what is possible!