Tencel Lyocell is a cellulosic fiber that originates from the cellulose of wood and through responsible and sustainable processes becomes a fiber with a soft and silky appearance.

The wood used for the creation of this fiber is that of eucalyptus tree. The consumption of water used in the production process of Tencel is 10-20 times lower than that of cotton. Although it is also a vegetable fiber, it therefore demonstrates greater eco-compatibility than cotton.

The first company to produce lyocell was Courtaulds Fibers Inc. in 1988, in the S25 experimental plant; only four years later, in 1992, they started marketing it, under the name Tencel. Only later the production expanded, and Lenzing AG, an Austrian company, also began to produce it under the trade name of Lenzing Lyocell.

Since March 2018 Lenzing AG has stopped marketing lyocell fiber under the name Lenzing Lyocell, and today produces the cellulosic fibers Modal and Lyocell using a single name for both: TENCEL. They are now differentiated as Tencel Lyocell and Tencel Modal.

The fiber is produced from crushed cellulose dissolved in NMMO-monohydrate, the resulting product is honey-like in consistency, but hardens in the processes that transforms it in a yarn. It is therefore distinguished from viscose which uses carbon sulphide and is in any case part of the cellulosic fibers. precisely due to the fact that very low-level chemicals are used during production, Lyocell has obtained the certificate with the European eco-label Oeko Tex 100.

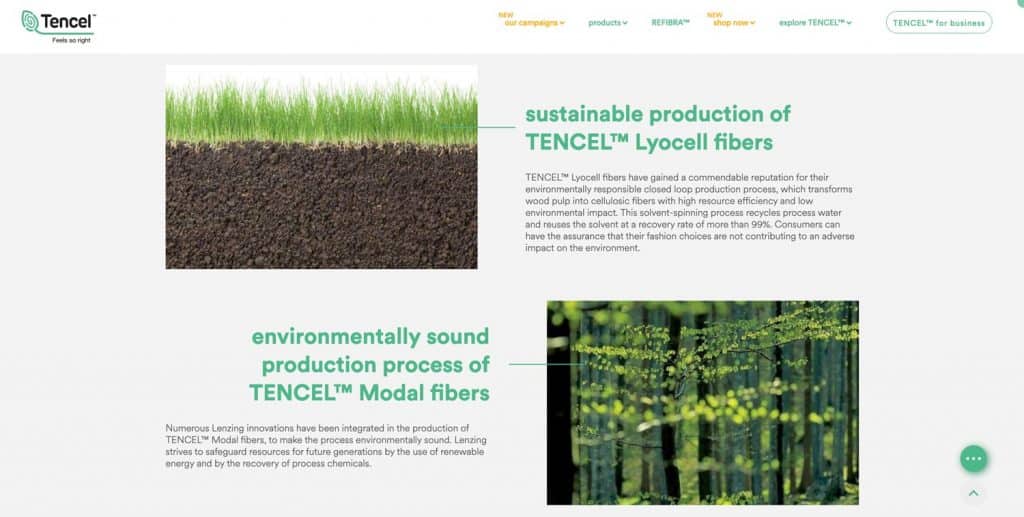

The production of Tencel Lyocell by Lenzing AG is revolutionary because the production process is based on a solvent spinning process, which uses non-toxic and almost 100% recycled solvents within the production cycle. This is a patented closed-loop process.

Although lyocell is biodegradable, if placed in a landfill it does not completely decompose. In any case, from specific studies, it appears that it can decompose in just 8 days in certain environments.

The wood used comes from specific FSC and PEFC certified forests, mainly of eucalyptus trees, but also of birch and oak. The land that is used is not suitable for agriculture, the cultivation of plants useful for the production of tencel is therefore not in competition with food production, as can be the case for the cultivation of cotton.

In general, today Tencel is made, from the point of view of treatment, in Austria, the United Kingdom, and also in the United States, but the essential trees for having it, the eucalyptus, come from South Africa. As for water consumption, eucalyptus trees do not need irrigation, but it does need to treat the pulp of this wood to transform it into Lyocell. The total bill is 154.7 liters of water per kilo of fiber, still much less than organic cotton that comes from California.

The main features are excellent resistance, good breathability and moisture absorption. Lyocell fabrics resist washing up to 40 ° C without any problem; if you wash at 60°C, however, you notice a shrinkage of about 5%. The hand is very soft, smooth and shiny, with a very fluid rendering of orthogonal fabrics or knitwear that use yarns produced by lyocell. The color rendering in the dyeing phase is also very good, the colors are in fact intense and rich thanks to the high absorption capacity of the fibers.

Among the advantages it should also be mentioned a greater moisture absorption than other similarly used materials: since the base is eucalyptus wood, capable of absorbing moisture in a natural way. The Tencel obtained does nothing but exploit the already intrinsic quality by differentiating itself from the cotton which absorbs on average 50% less. In addition to absorbing moisture, Lyocell is also hypoallergenic because it can filter bacteria and other pollutants.

Modal mentioned above is another cellulosic fiber, similar to Tencel, it is also part of the world of viscose, and is created from cellulose extracted from beech trees. As a date of creation it is prior to Tencel, shortly after the creation of rayon from which it differs only in the fact of coming specifically from the pulp of cellulose exclusively of beech, while rayon is created with cellulose of different trees.

The aforementioned company Lenzing AG is one of the best known Modal producers in the world. Unlike other Modal fibers on the market, Modal by Tencel is protected by a global certification system and is therefore a fiber that we can safely define as sustainable.

The smooth surface of the Modal fiber prevents the deposit of minerals during washing and therefore hardening even after many washes and guarantees the longevity of the fabrics. To the touch, modal is soft and elastic like a microfiber, has an excellent snug fit, but remains much more delicate on the skin and does not create discomfort and irritation, which is why it is widely used for underwear.